ModuLimb

ModuLimb is a low-cost, adjustable pediatric prosthetic leg that adapts in height and fit as children grow, ensuring comfort, durability, and quick local manufacturing within days.

ModuLimb addresses a clear gap in pediatric below-knee care, as most devices do not grow along with the child. Nearly 1 in 200 children worldwide live with limb differences, yet families face costly, distant and stigma-laden care pathways that delay fittings and follow-ups. Rapid growth drives replacement cycles of roughly 12–24 months, so kids outgrow sockets and pylons before they’ve mastered gait training, compounding discomfort, mobility loss and clinic time. Fieldwork and literature shaped the brief to make a limb that adapts in height and circumference, is tool-free to adjust, affordable to produce locally, and resilient for active play. Interviews with prosthetists, caregivers and rehab staff emphasized soft-tissue comfort, hygiene, lighter mass, shock management and aesthetic acceptance to reduce stigma in schools and public spaces. The design response prioritizes user agency of letting caregivers tune fit day-to-day while embedding a support lifecycle from assessment to follow-up so children can move, play and grow with confidence. Methods included site visits, expert reviews, and rig tests to translate insights into measurable objectives of growth-ready adjustability, low cost, skin-safe materials, and easy serviceability close to home.

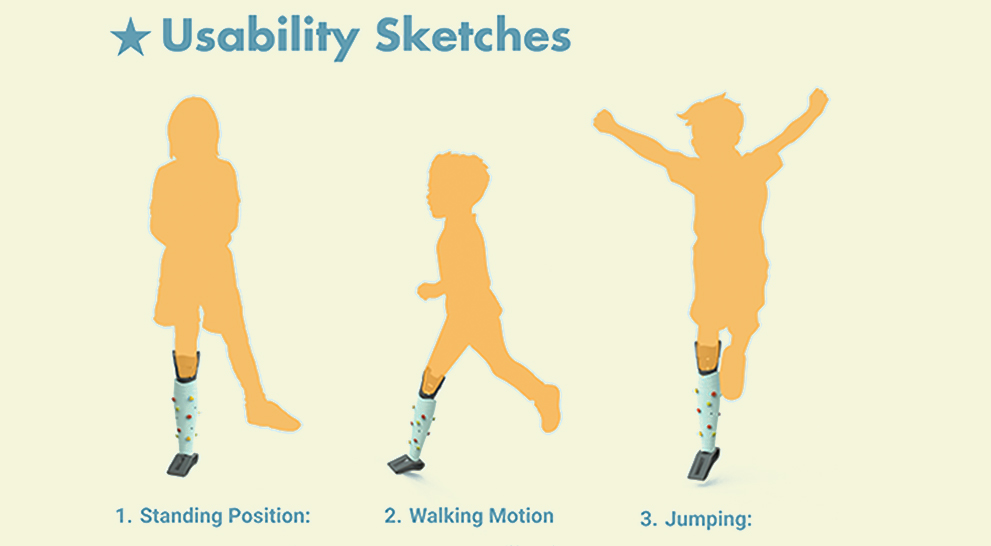

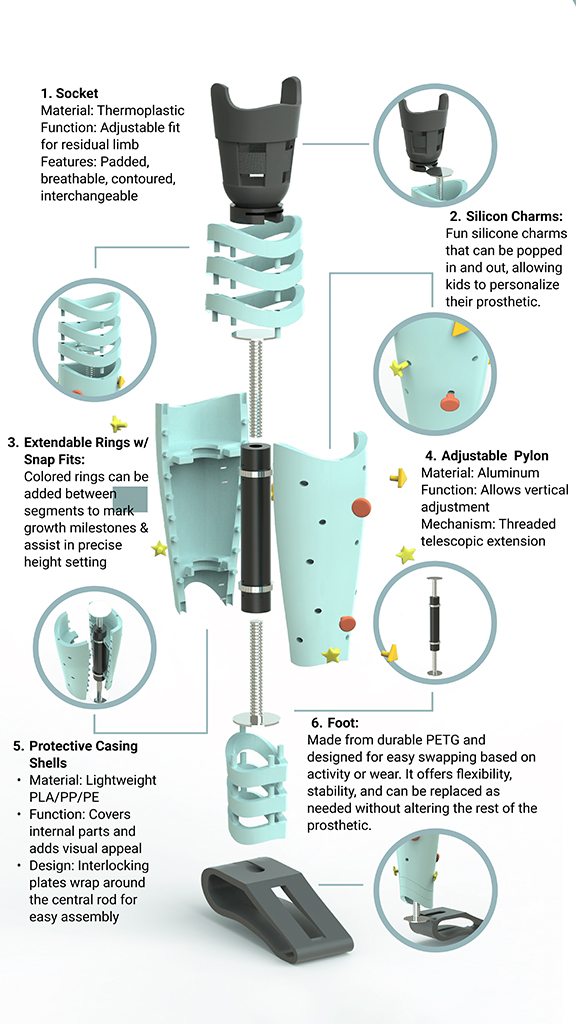

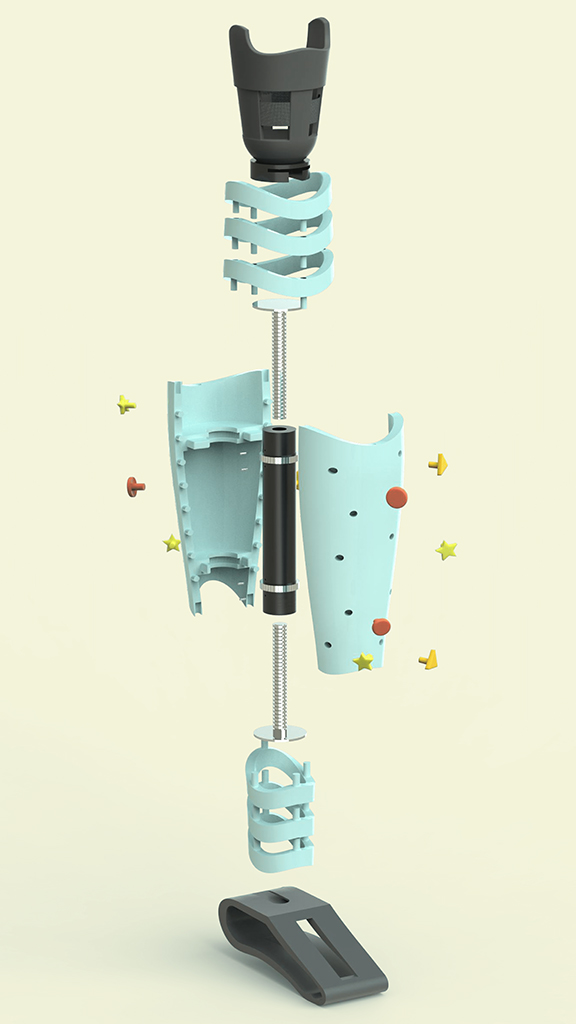

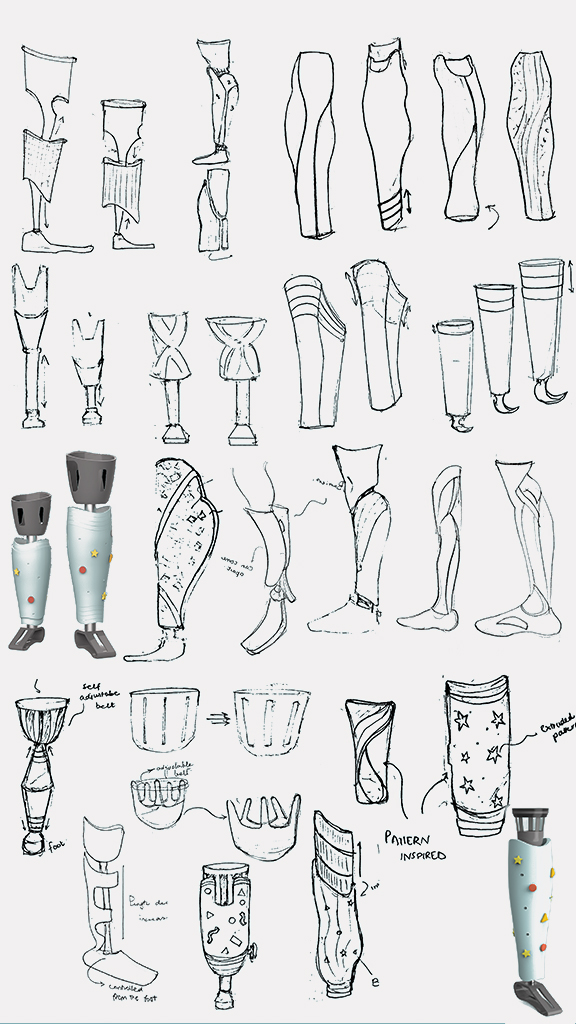

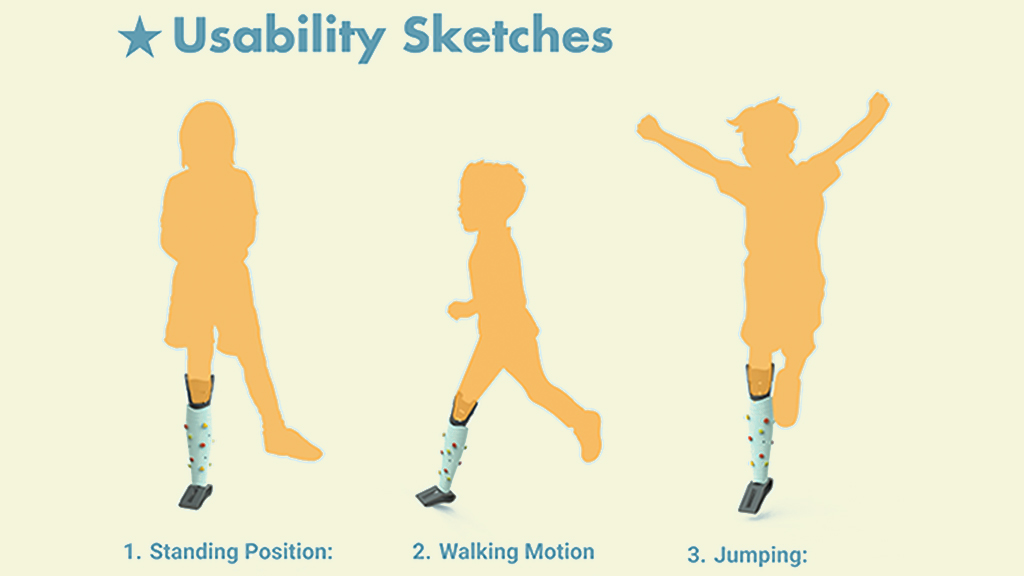

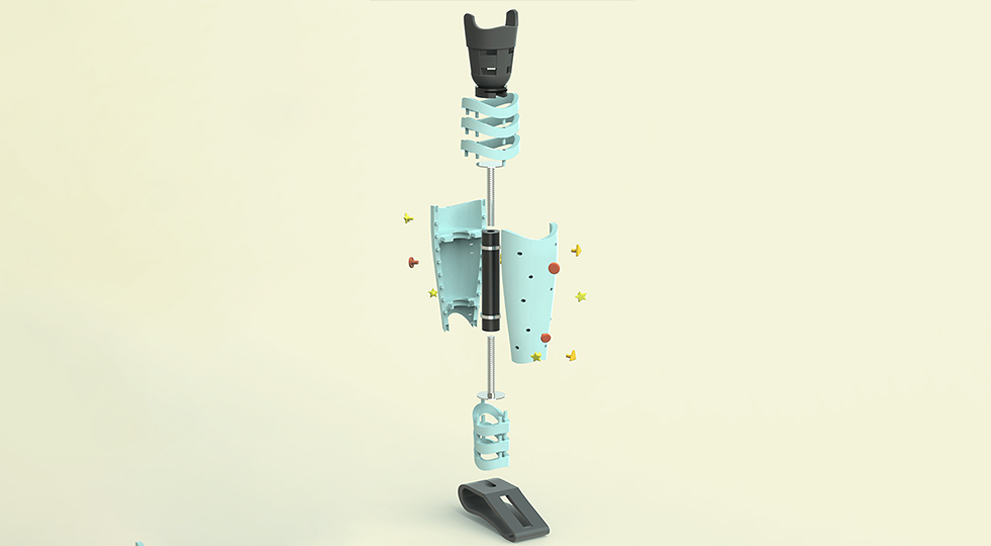

The design meets these needs through three growth-accommodating modules. The casing is a ring-based shell that expands or contracts with the child’s growth and uses quick-release closures for easy, tool-free adjustment and hygiene. The pylon is telescopic and twist-adjusted through threaded tubes that lengthen or shorten with a small disc, locking securely for repeatable changes. The socket has soft liners and adjustable straps in a flexible frame, reducing pressure points and improving proprioception. Materials are chosen for function, including silicone or gel for cushioning, TPU for durability, PLA/PP hybrids for shells, carbon-filled polymers for rings, and standard hardware for easy servicing. Assembly is simplified as parts snap, thread, or index together, reducing clinic time. Height and volume changes are visible and repeatable, while worn parts can be replaced individually. The ergonomic design keeps a low profile with rounded edges and smooth surfaces to prevent snags at school or during play. A universal foot interface supports common pediatric feet and cosmetic covers. Scale marks help caregivers with adjustments, while safety locks prevent over-extension. Color panels and stickers add personalization, encouraging ownership and acceptance in daily use.

The socket, pylon, and foot are based on anthropometric ranges for children aged 3 to 12, with growth steps that follow typical changes in height and calf size. Local manufacturing uses simple tools such as FDM printing, trimming, drilling, and hand assembly with materials from regional suppliers. This process allows delivery in 7 to 10 days and ensures affordable service. Costs remain family-friendly since worn parts can be replaced individually without a full refit. Each device is tested for fit, alignment, and load paths before handover, and caregivers receive guidance on use, skin care, hygiene, and safe activity. Two user groups shape the presets: ages 3 to 7 need soft suspension, easy closures, and extra padding for play, while ages 8 to 12 require firmer support, sport-ready durability, and quicker adjustments for growth spurts. The service model relies on simple records, reminders, and photo checks to reduce travel while keeping clinician oversight. Sustainability is built in with modular spares, recyclable shells, and small-scale repairs. The design also allows upgrades such as energy-storing feet, toe and heel tuning, auto-adjust options, and culturally relevant colors or covers that make the device a source of pride.